Board and Sheet Feeders

As fast as our auto feeders supply material to your process, our stackers and unloaders can take it away!

Up to a full 3200mm x 2200mm (126 in x 87 in) in offload area, we have solutions for your portrait or landscape oriented lines and can be designed to deliver sheets for stacking straight through or at right angle to various finishing process. In addition, we have the ability to stack (and feed) an unprecedented 1500mm (60 inches) in a perfectly aligned stack height. To boot, our vacuum plenum design assures you will see no witness marks due to the suction handling process.

Let us work with your specs to create the right engineered solution for your application!

Board & Sheet Stacker Systems

Large Format Stacking – up to 3.2 x 2.6M

Compensator – Point Pickup

- Board Stacker – Gantry Compensator

- Board Stacker – Pivot

- Board Stacker 4-Post

Plenum – Zone Pickup

- Board Stacker – Gantry Plenum

Small Format Sheet Stacking up to 1.0 x 1.0M

- AutoStacker

Board Stacker – Gantry – Compensator

Key Features

Options include

- 1 to 4 material lanes

- 48″ Stack Height

Materials

- Up to 3.3 x 2.65M (130″ x 104.3″)

(STAR) Pallet to Pallet System Component

CE Certified

Pivot Feeder/Stacker

Meeting the demands of graphic producers, IMC has developed a unique style of feeder capable of processing pallets of material reaching a full sixty inches in stacked height. As its name implies, the Pivot Feeder employs pivoting motion to pick and place single sheets from the pallet to a digital printer, cutter or any other board feeding application. Likewise, the Pivot Stacker is the mirrored bookend to the Pivot Feeder and is used to remove sheets from your process and re-stack back directly to a pallet.

Key Features

- Pallet Fed

- 60” stack height

- Back Alignment

Options include

- 1 or 2 material lanes

- Side Alignment Table ( Option )

Materials

- Up to 3.2 x 2.2M (126″ x 86.6″)

(STAR) Pallet to Pallet System Component

CE Certified

4-Corner Post Stacker

The 4-Corner Post Stacker is the mirror image to the 4-Corner Feeder, offering the same customization suited for board and finished goods accumulation.

Key Features

- Pallet Fed Auto Load

- Lower cost solution

- Fully Automated

Options include

- 1 to 4 material lanes

- Front and Side Alignment

- 48″ Stack Height

Materials

- Up to 3.2 x 2.2M (126″ x 86.6″)

Board Stacker – Gantry – Plenum

Key Features

- Pallet Fed

- 3 Feeds per minute

- Fully Automated

- Allows Roll to Roll function

Options include

- 1 to 4 material lanes

- Front and Side Alignment

- 48″ Stack Height

Materials

- Up to 3.3 x 2.65M (130″ x 104.3″)

(STAR) Pallet to Pallet System Component

CE Certified

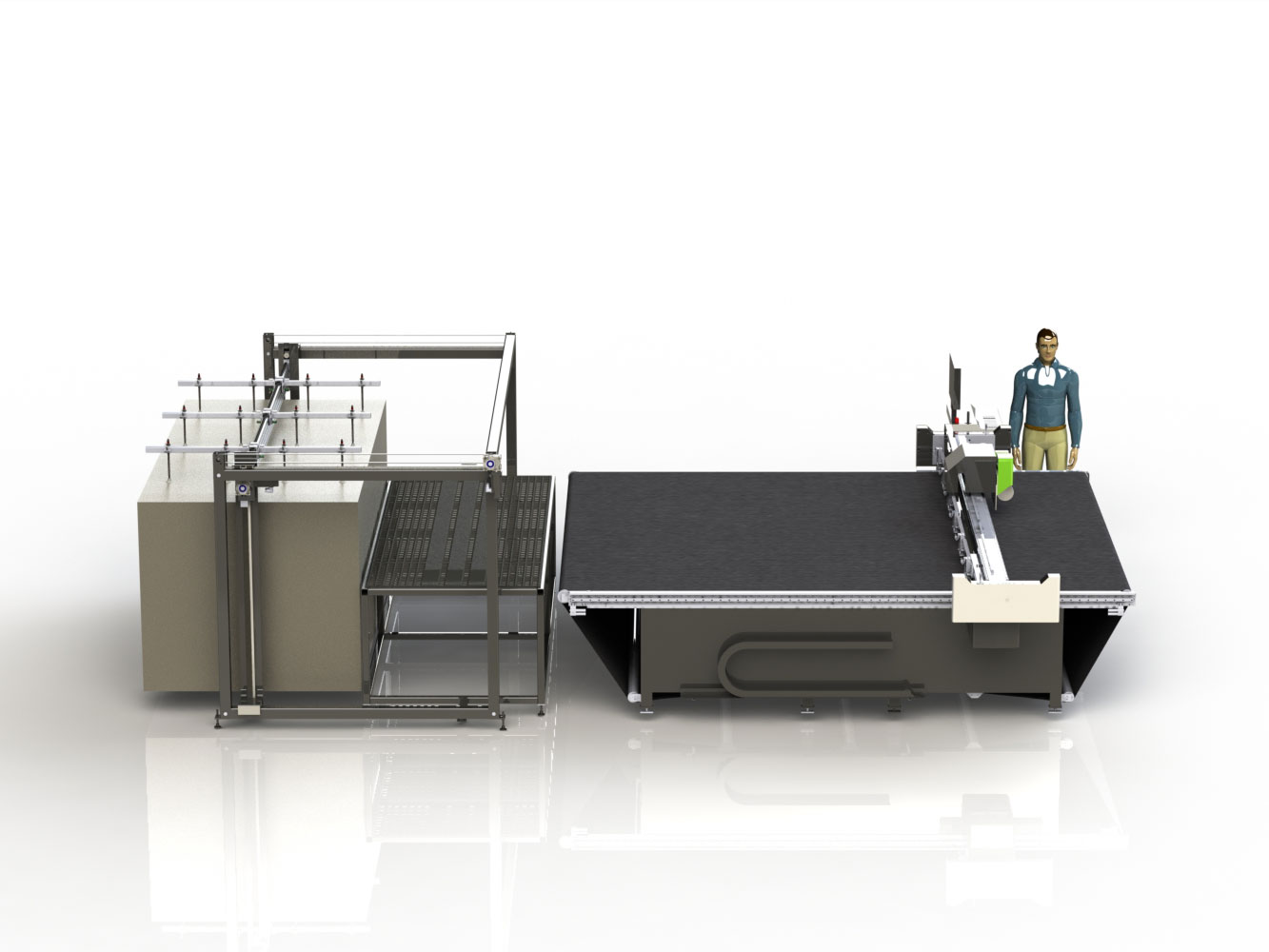

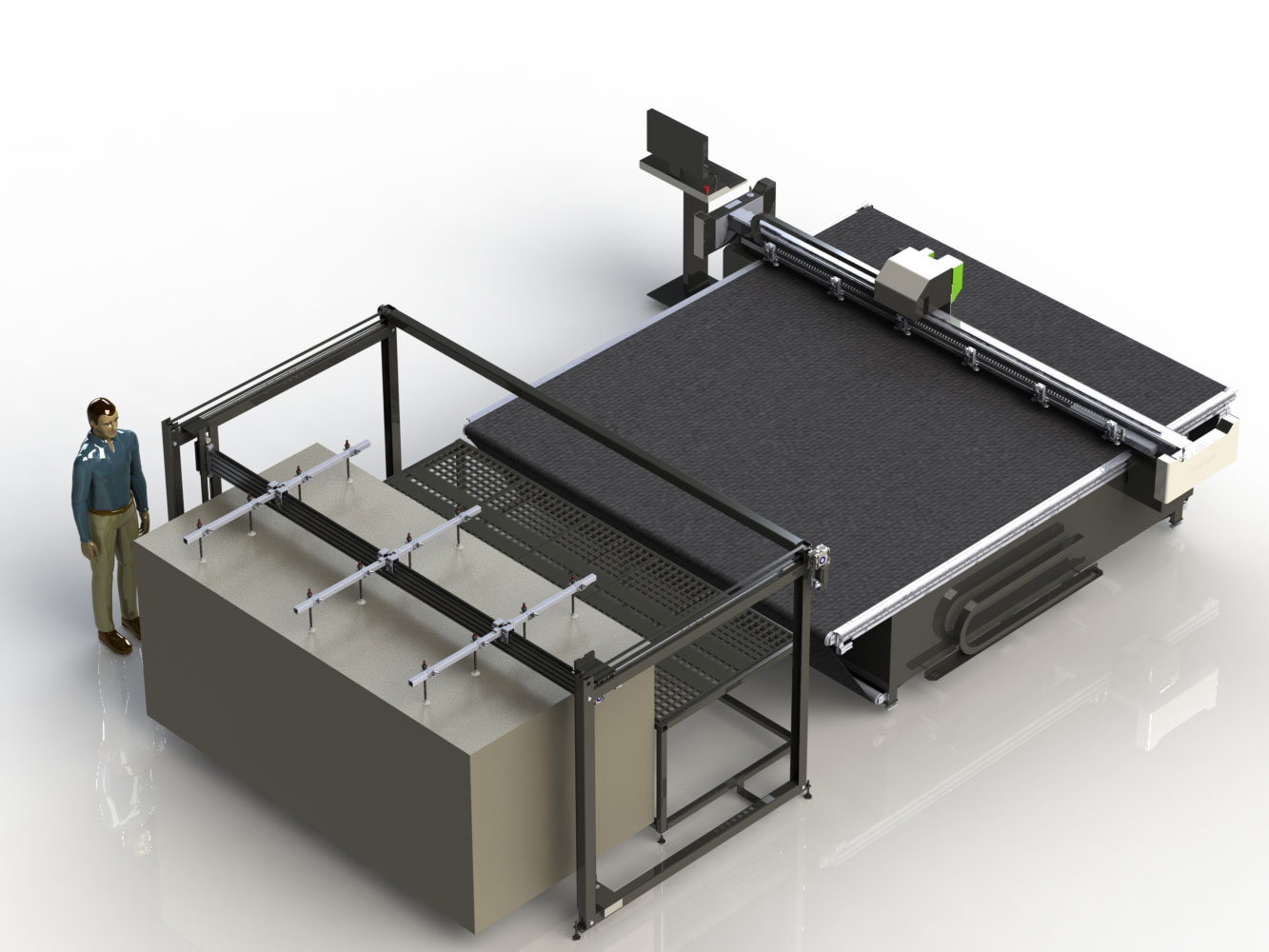

High Speed Stacker

The High Speed Stacker (HSS) is the offloading complement to the HSSF and too processes materials under 32”W x 26”L (810Wx660L mm). Easily configurable for any cut file, 16 independently controlled vacuum pick points extract the cut form from the scrap matrix and place cutouts on to an offload table.

Manual Systems

The Manual Offload Table is a gravity fed slant table which offers an economical method to help reduce delays between cut indexes by sliding cut product and its scrap off the end of the driven cutter belt. Guide pins help to organize the cut product pile along the length of the table depending on its size. The table is made portable to come easily in and out of line when needed.