Paper cup equipment manufacturers the world over turn to Infinite Motion Control for an array of paper/plastic cup automation converting machinery designed to deliver a new level of productivity in paper cup equipment. This is paper converting equipment engineered expressly for the unique demands of today’s highly competitive paperboard packaging industry, not adapted to it. Our aim is to be a trusted partner for our customers in meeting every challenge of supplying ancillary equipment and services to the paper and plastic cup industry.

New-generation technology meets rugged, long-life durability with IMC paper cup converting machinery. Beverage containers, yogurt containers, ice cream containers – they all require infinite care and high-volume capabilities in their manufacture. This is why, if you’re a paper cup or container manufacturer serving today’s food beverage packaging industry, Infinite Motion Control automation equipment will make a difference in your forming operation – and your bottom line.

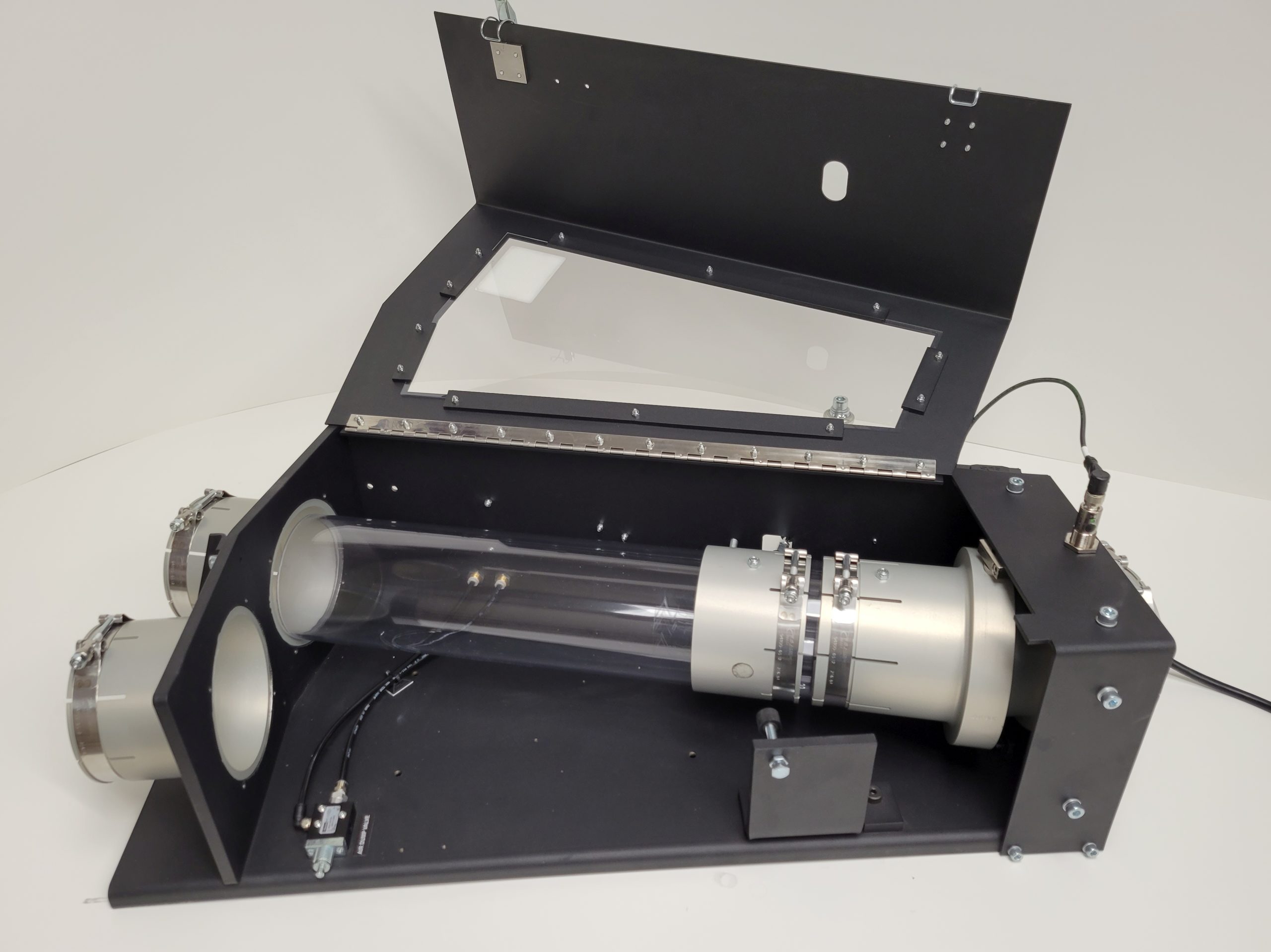

Diverters

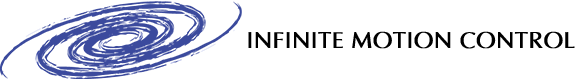

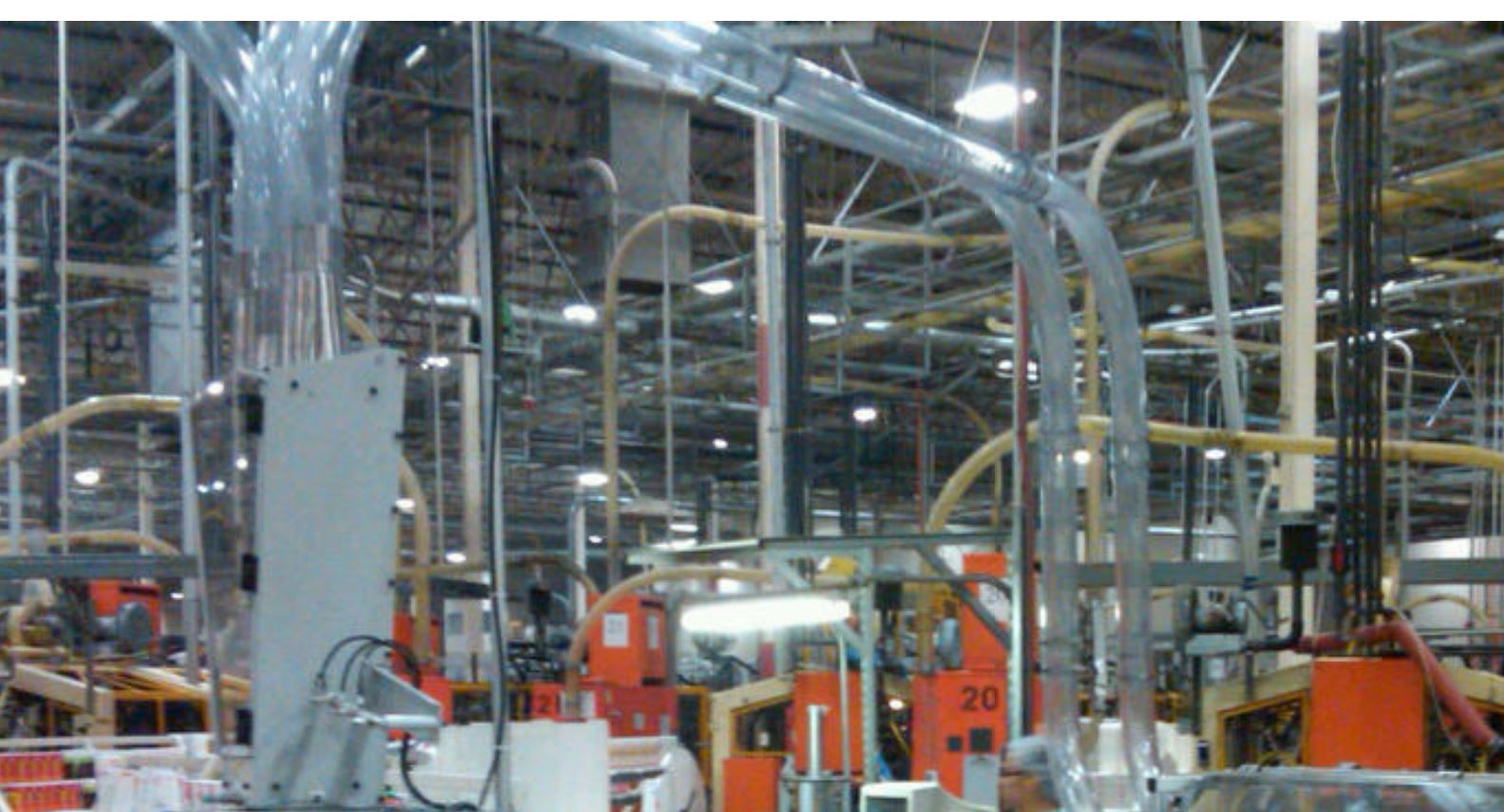

In typical cup producing factories, a network of tubing carries cups from the former to inspection or packaging. IMC Cup Diverters are the track switches to automatically change routing between these processes.

In these applications, IMC’s Paper Cup Diverter has proven to be a reliable, trouble-free, and low-cost cup-diverting solution for paper cup manufacturers and paper cup production throughout the world. The IMC pneumatic paper cup diverter provides jam-free, on-the-fly diverting of paper cups at rates of over 300CPM.

IMC cup diverters have been adapted to a wide range of cup diverting applications, including:

- Diverting the first paper cups out of production when the cup former begins running

- Diverting paper cups during production to different packing stations

- Diverting sample paper cups to inspection stations

- Diverting defective paper cups out of production

- Paper cup sorting applications

- IMC will customize our versatile paper cup diverter system to meet your unique requirements.

Paper Cup Diverter Includes:

- Air Shut-off Valve

- Regulator

- Gate Control Valve

- Tube connections sized to your specifications

Diverter platforms

- Standard – 4oz – 24oz – Up to 3.8” Rim Diameter

- XL Diverter – 20oz – 32oz – Up to 5” Rim Dia.

- Servo Diverter – High Cycle & Speed Applications with selectable frequencies.

- Tube Diverter – Several popular sizes

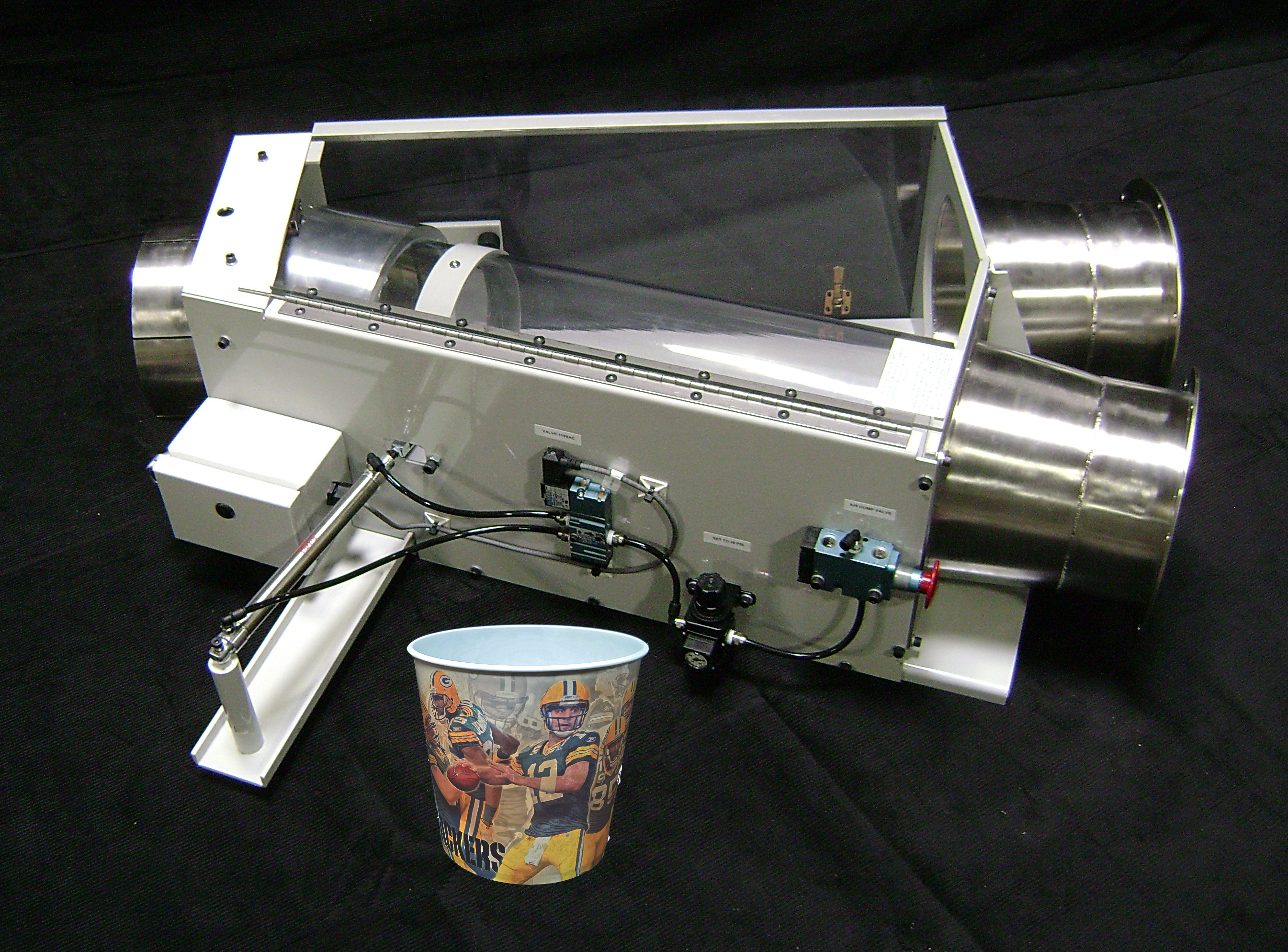

Diverters can be used for extra-large cups and containers

- Large Diameter ‘Popcorn’ Tub containers up to 7.4” Diameter

- Large Diameter Cups – up to 5” Rim Diameter

- Rectangular shapes

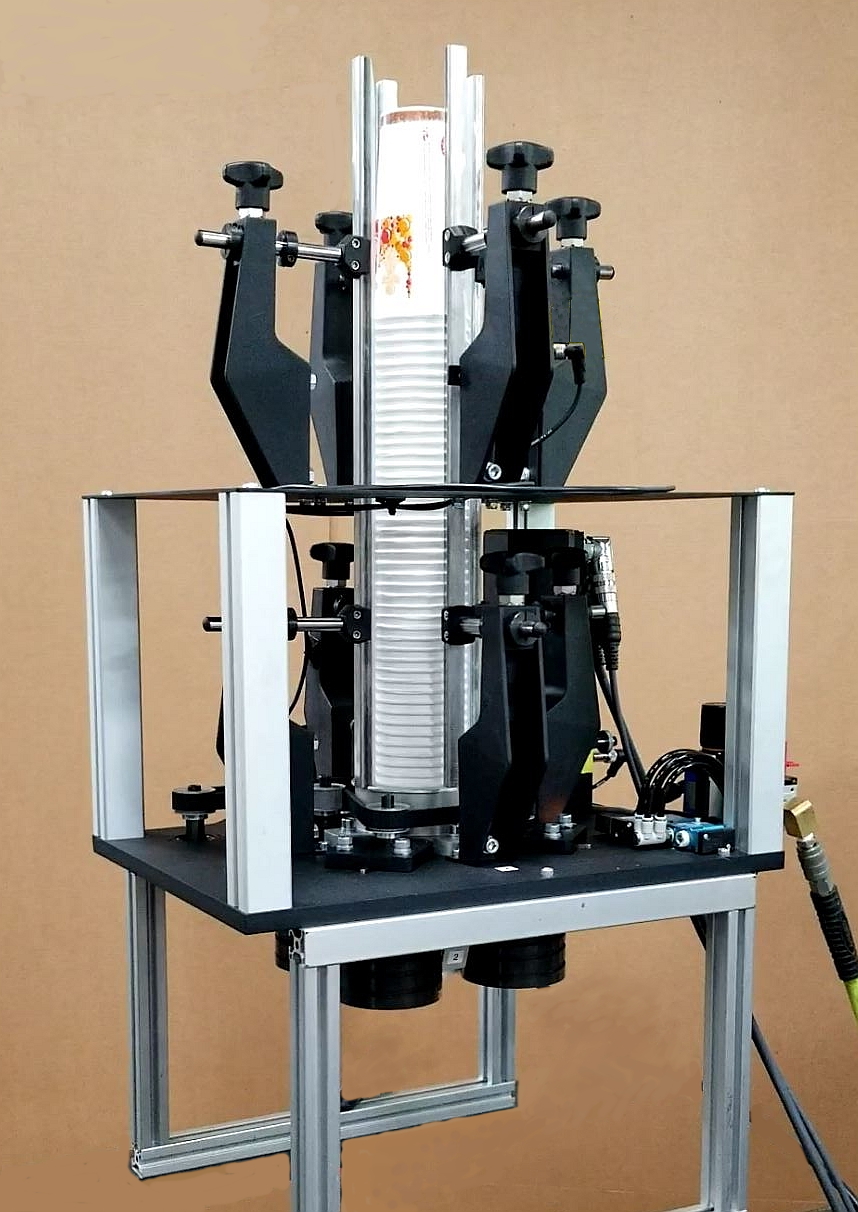

Screw Feeders

Infinite Motion is a world leader in high speed cup conveyance. An essential element to cup automation is IMC’s high speed cup infeed module designed to feed cups and containers of various sized diameters at speeds up to 325 CPM.

These units work perfectly for overwrap, labeling, or inspection operations and our modular design is easily adaptable and customizable to integrate in many feeding applications. This robust 4-screw feeder design accurately feeds cups either in-line or off-line from the cup forming process

Custom Equipment

Although we have the knowledge and ability to design custom equipment, we focus on volume designs. If you have a recurring need, please reach out and see what we can do for you.