Easy-to-operate, our sheet feeders and stackers are the perfect complement for your printing and finishing automation needs. For nearly 20 years we’ve designed and built reliable, user-friendly, and low maintenance feeders and stackers in the U.S.A. (regularly under private label). Our equipment features heavy-duty thick gauge steel construction and is built with trusted name brand name components. Our material handling systems are in operation throughout the world by many leading graphics producers.

Our goal is to become your trusted partner and solution provider in the digital print and finishing industry.

Feeders

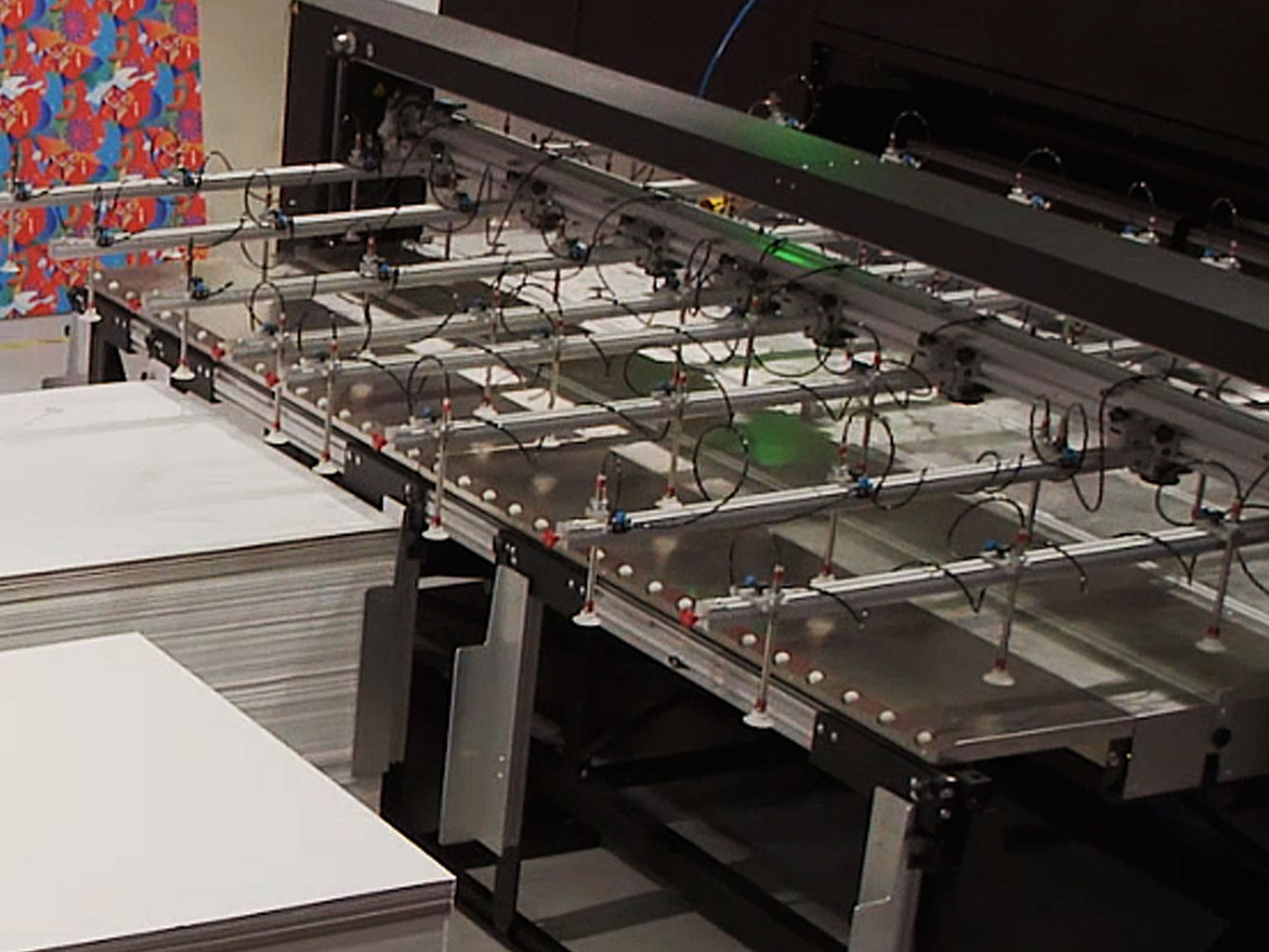

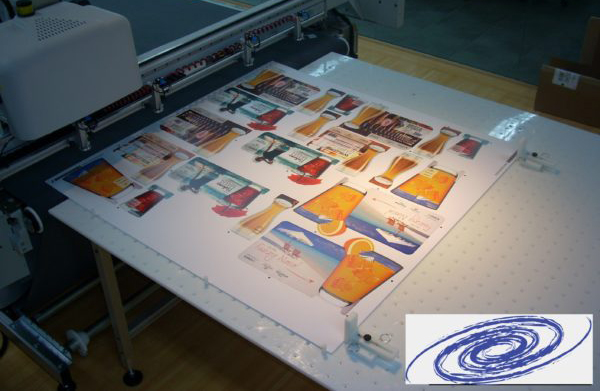

The first and essential building block of digital line automation starts with fast and efficient sheet feeding. IMC has a wide assortment of in-feeders and board loaders to suit your needs. Narrow to wide format, B size paper to large format signage, we have the right solution to fit your printing or finishing application.

We offer several processing options including pallet feeds, table feeds, board flipping, board draggers, alignment tables, print registration, and much, much, more. Contact us to learn how we can effectively service your unique needs. Let us help you increase your productivity throughput by automating your digital line today.

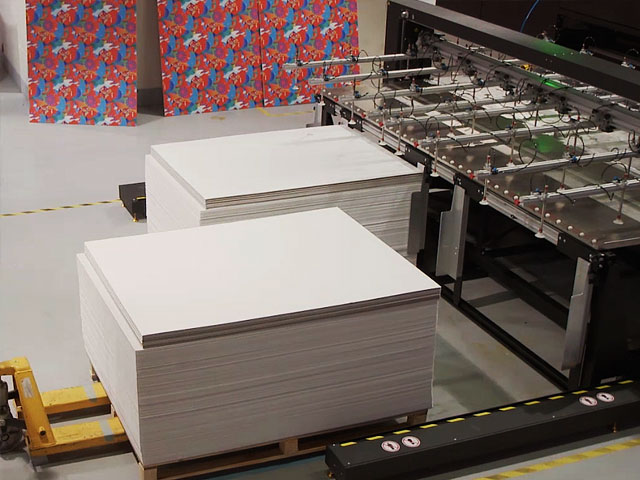

Automatic Stackers

As fast as our auto feeders supply material to your process, our stackers and unloaders can take it away!

Up to a full 3200mm x 2200mm (126 in x 87 in) in offload area, we have solutions for your portrait or landscape oriented lines and can be designed to deliver sheets for stacking straight through or at right angle to various finishing process. In addition, we have the ability to stack (and feed) an unprecedented 1500mm (60 inches) in a perfectly aligned stack height. To boot, our vacuum plenum design assures you will see no witness marks due to the suction handling process.

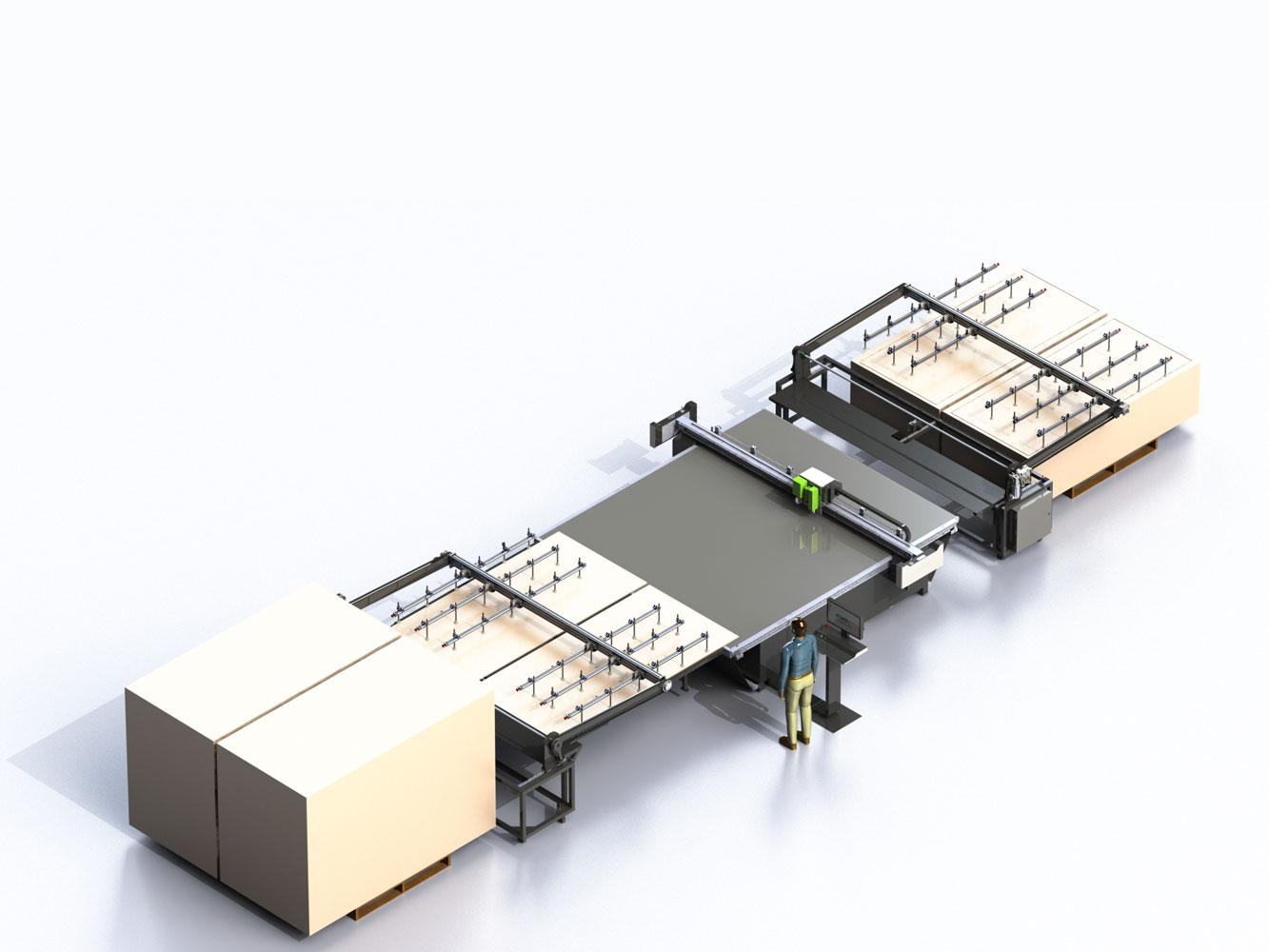

Pallet to Pallet

IMC utilizes pallet to pallet material control, this allows system manufacturers to have consistent feeding from pallets and placement back to pallet that allows customers to save time and avoid costs.

Large Format – up to 3.2 x 2.6M

- Gantry

- Pivot

- 4-Post

- Semi-Auto Board Feeder

Small Format up to 1.0 x 1.0M

- Polar 750 Sheet Feeder

- Autofeeder

- Hi-Speed Feeder

- Stacker

Ancillary Equipment

- Scissor lift

- Manual Table

- Lift table

Options

Picking Options

Feeders can utilize a variety of standard vacuum cups while the stacker can use vacuum cups or IMC’s Proprietary Plenums to handle cut boards or porous materials.

Edge Registration

When accuracy is critical, edge registration is quite practical to align the front, trailing, and sides of advancing rigid and flexible sheets for any in-line digital cut or printing application. IMC’s alignment tables easily bring into line one or multiple sheets across in precise unison for accurate square feeding. An optional air assist table is available for suspending flexible materials on a cushion of air to help reduce friction during the alignment process. Fast and exact, Infinite Motion’s has the best alignment technology for your application.

Polar 750 Sheet Feeder

Infinite Motion Control introduces their new small format sheet feeder for the digital finishing and printing market. The Polar 750 Sheet Feeder features a Roll In/Roll Out portable design able to run a variety of materials up to a maximum size of 750mm W x 1050mm L (29.5 in W x 41.3 in L).

This fully automatic design feeds one sheet at a time from a maximum stack height of 305mm (12.0in) at a feed rate of two sheets/min. and features:

Suction cup technology- quickly adjustable to accommodate any size sheet.

Stack Guide-side brush guides ensuring consistent sheet separation.

Air Knife Separator-for hard-to-run static materials.

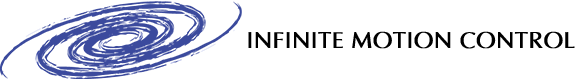

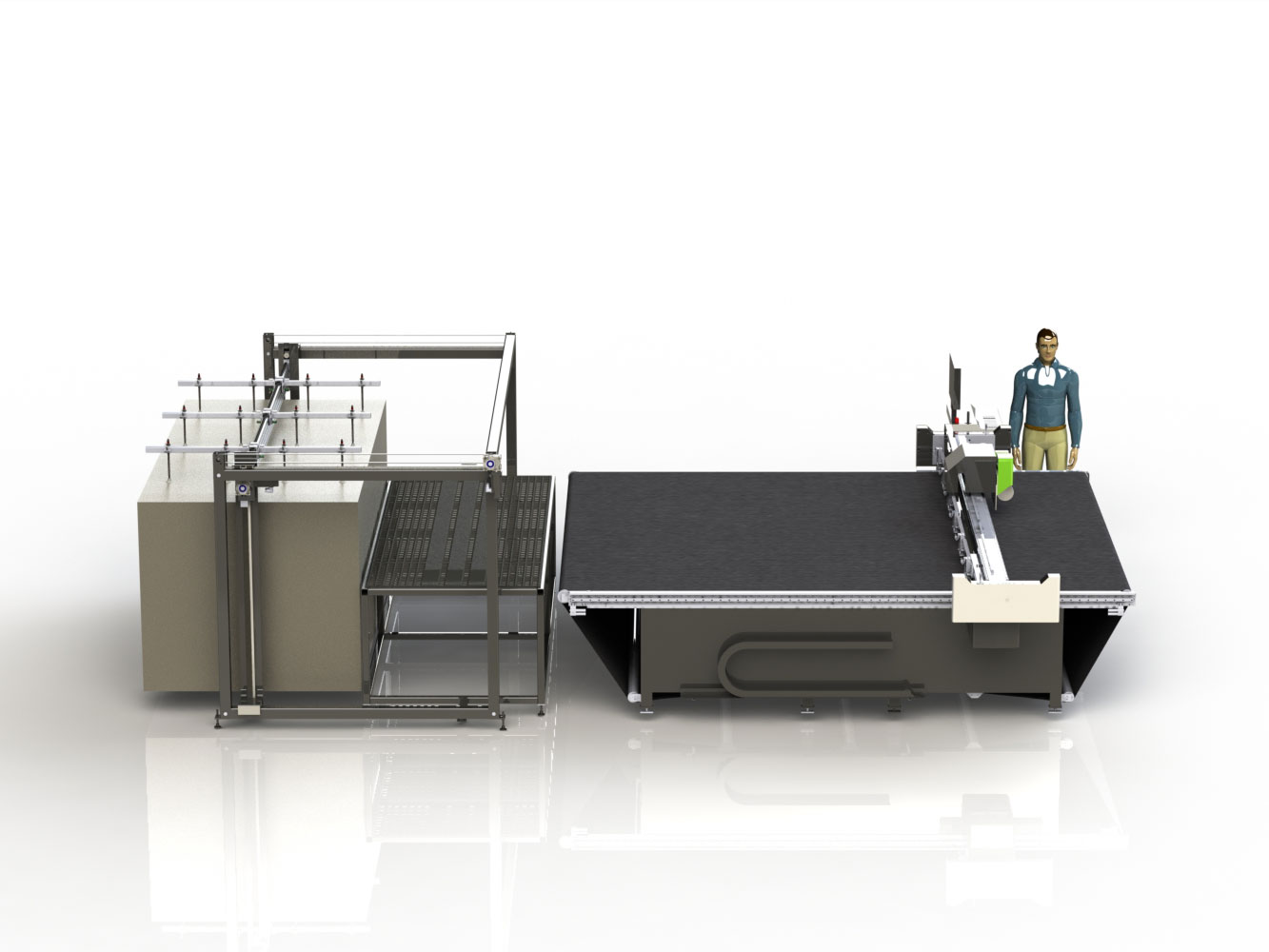

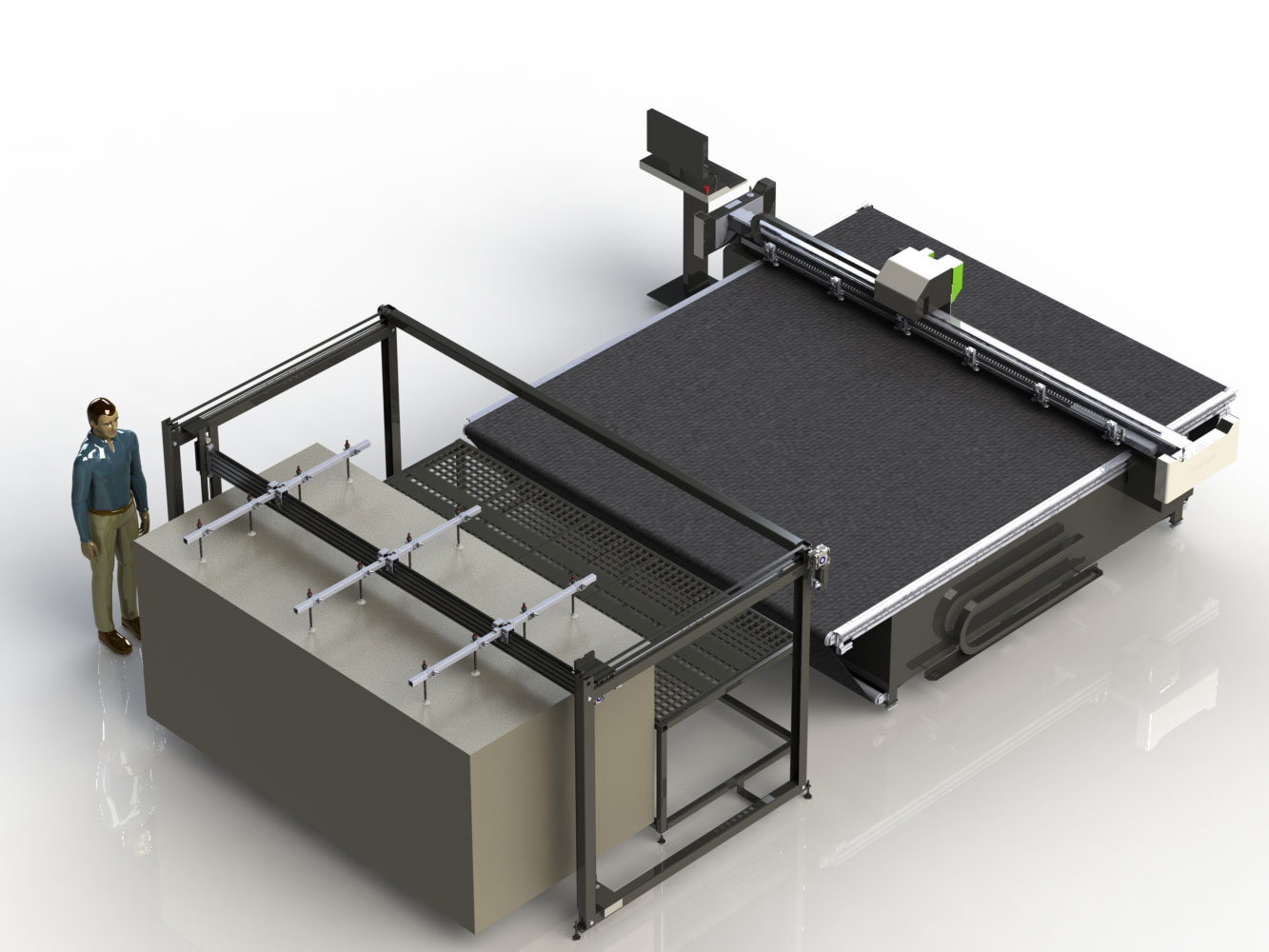

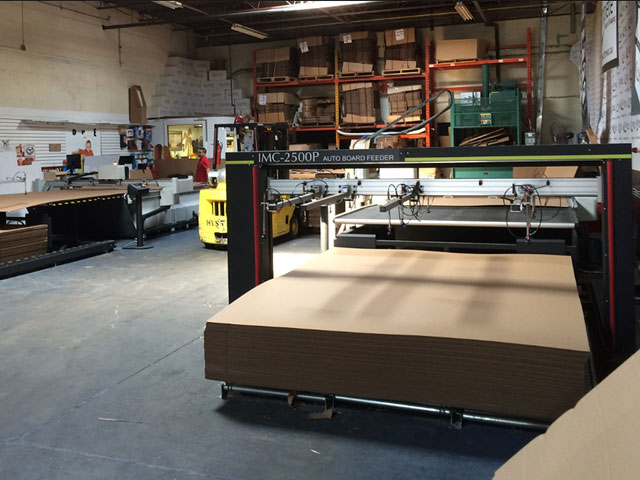

Board Feeder/Stacker – Gantry

Our most proven and versatile pick and place systems, without a doubt, are our 2-axis gantry feeders and stackers. Through our parterned organizations, Infinite Motion Control has the largest installed base of gantry automation serving the Print and Digital Finishing markets in the world.

For a custom solution, please contact us.

Key Features

- Pallet Fed

- 3 Feeds per minute

- Fully Automated

- Allows Roll to Roll function

- Pallet to Pallet System Component

- CE Certified

Options include

- 1 to 4 material lanes

- Front and Side Alignment

- 50″ Stack Height

Materials

- Up to 3.3 x 2.65M (130″ x 104.3″)

Pallet to Pallet – IN ACTION

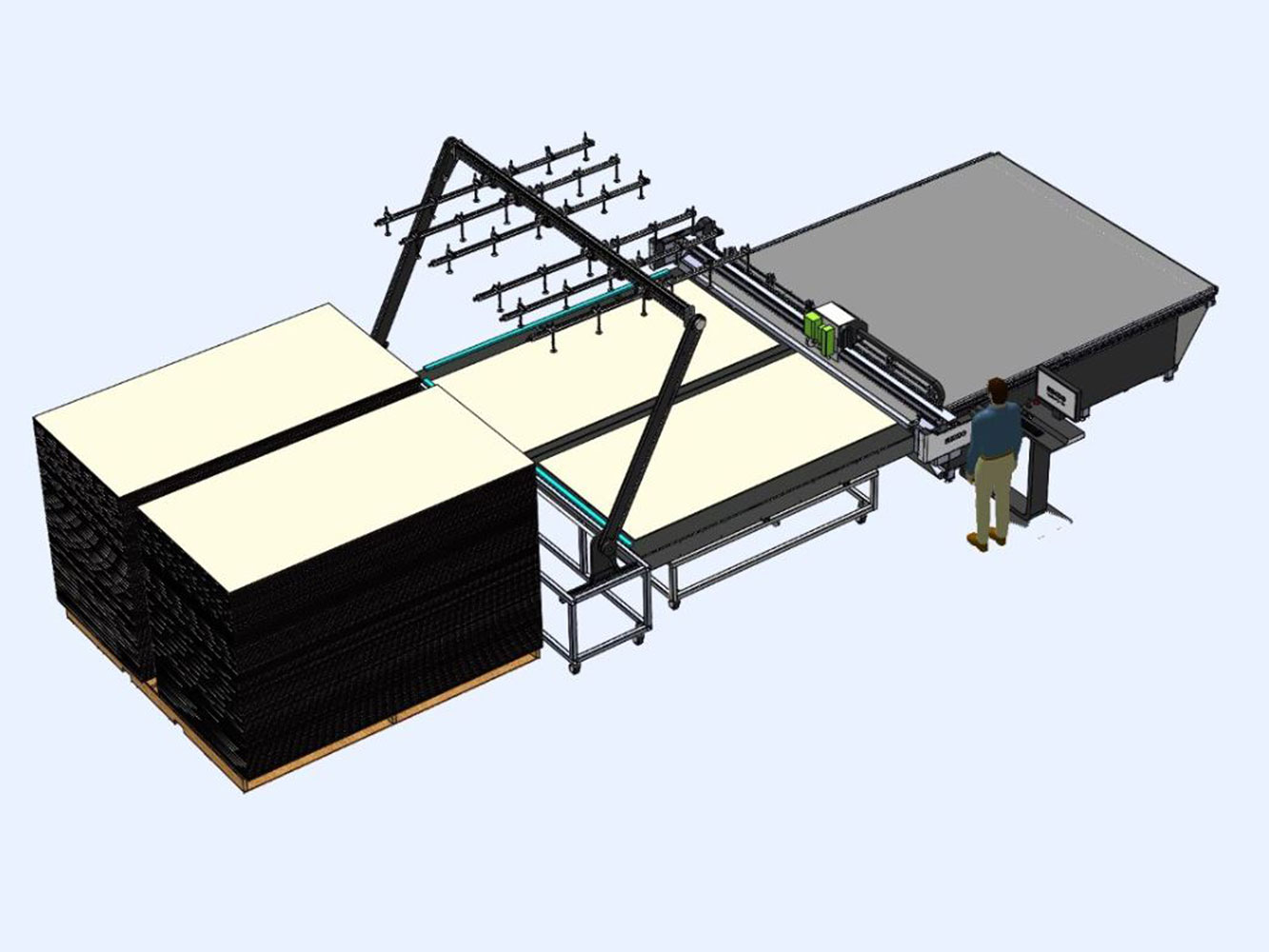

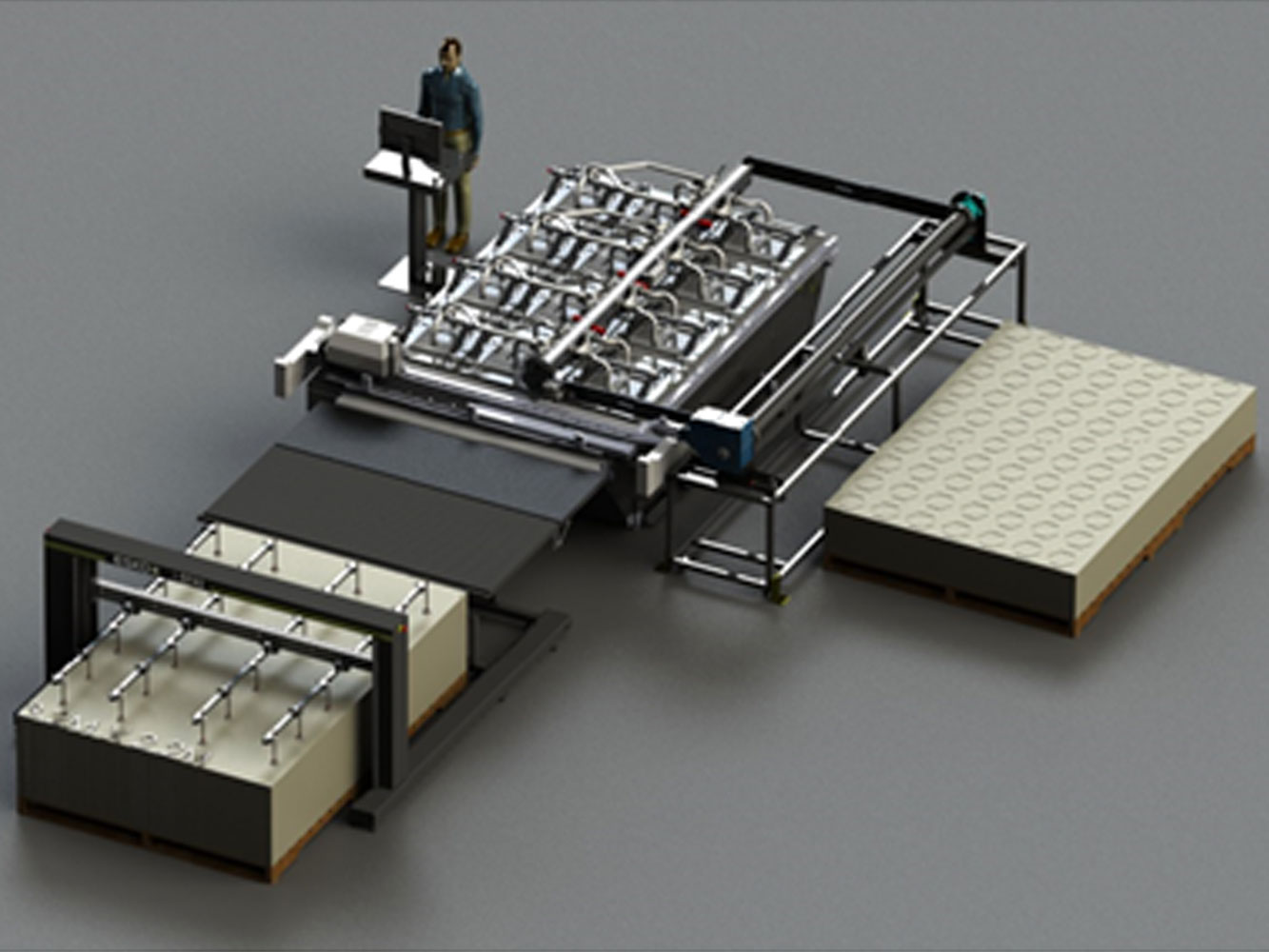

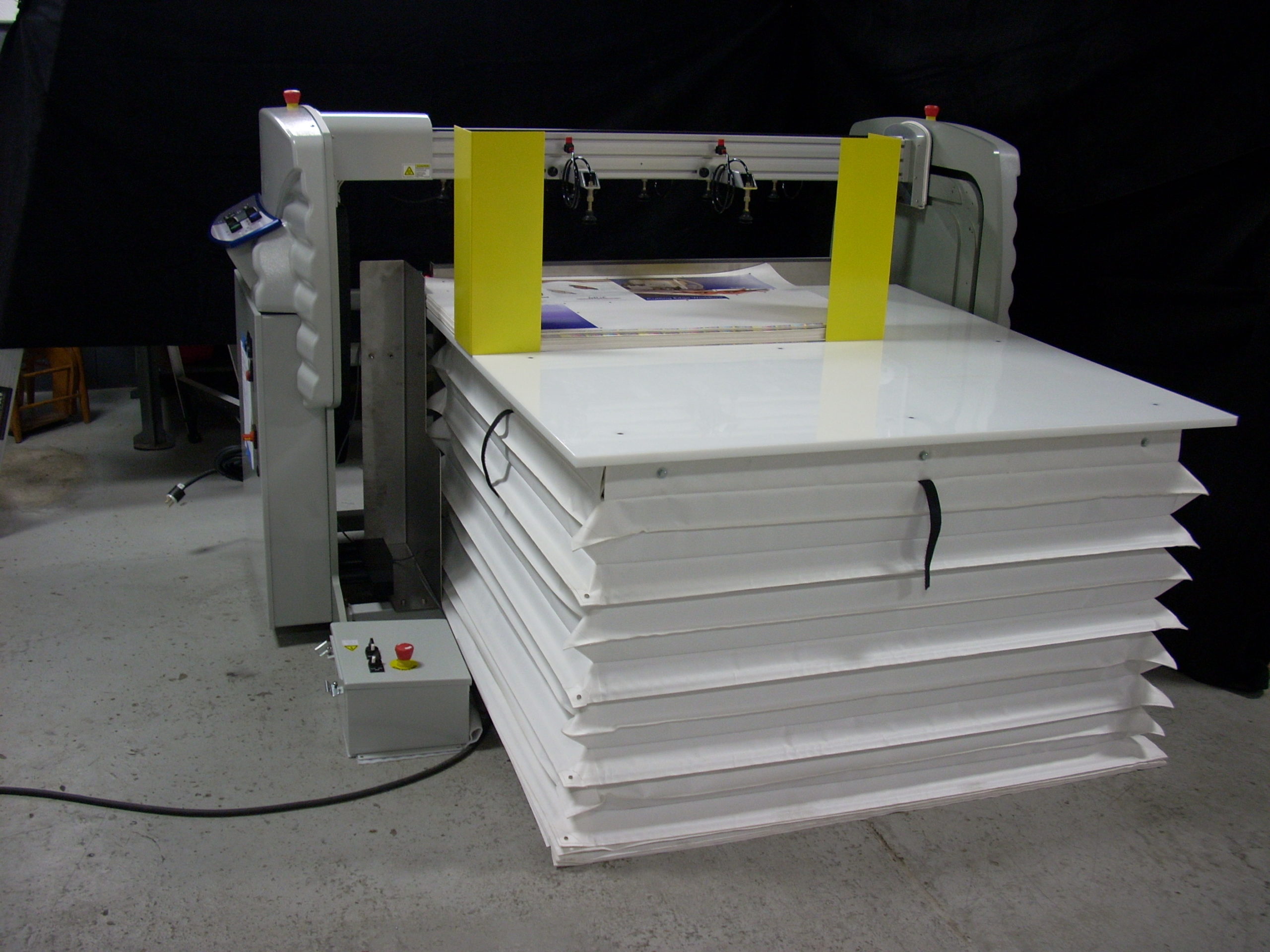

Pivot Feeder / Stacker

Meeting the demands of graphic producers, IMC has developed a unique style of feeder capable of processing pallets of material reaching a full sixty inches in stacked height. As its name implies, the Pivot Feeder employs pivoting motion to pick and place single sheets from the pallet to a digital printer, cutter or any other board feeding application. Likewise, the Pivot Stacker is the mirrored bookend to the Pivot Feeder and is used to remove sheets from your process and re-stack back directly to a pallet.

Key Features

- Pallet Fed

- 60” stack height

- Back Alignment

- Pallet to Pallet System Component

- CE Certified

Options include

- 1 or 2 material lanes

- Alignment Table

- 90 Degree take-off

Materials

- Up to 3.2 x 2.2M (126″ x 86.6″)

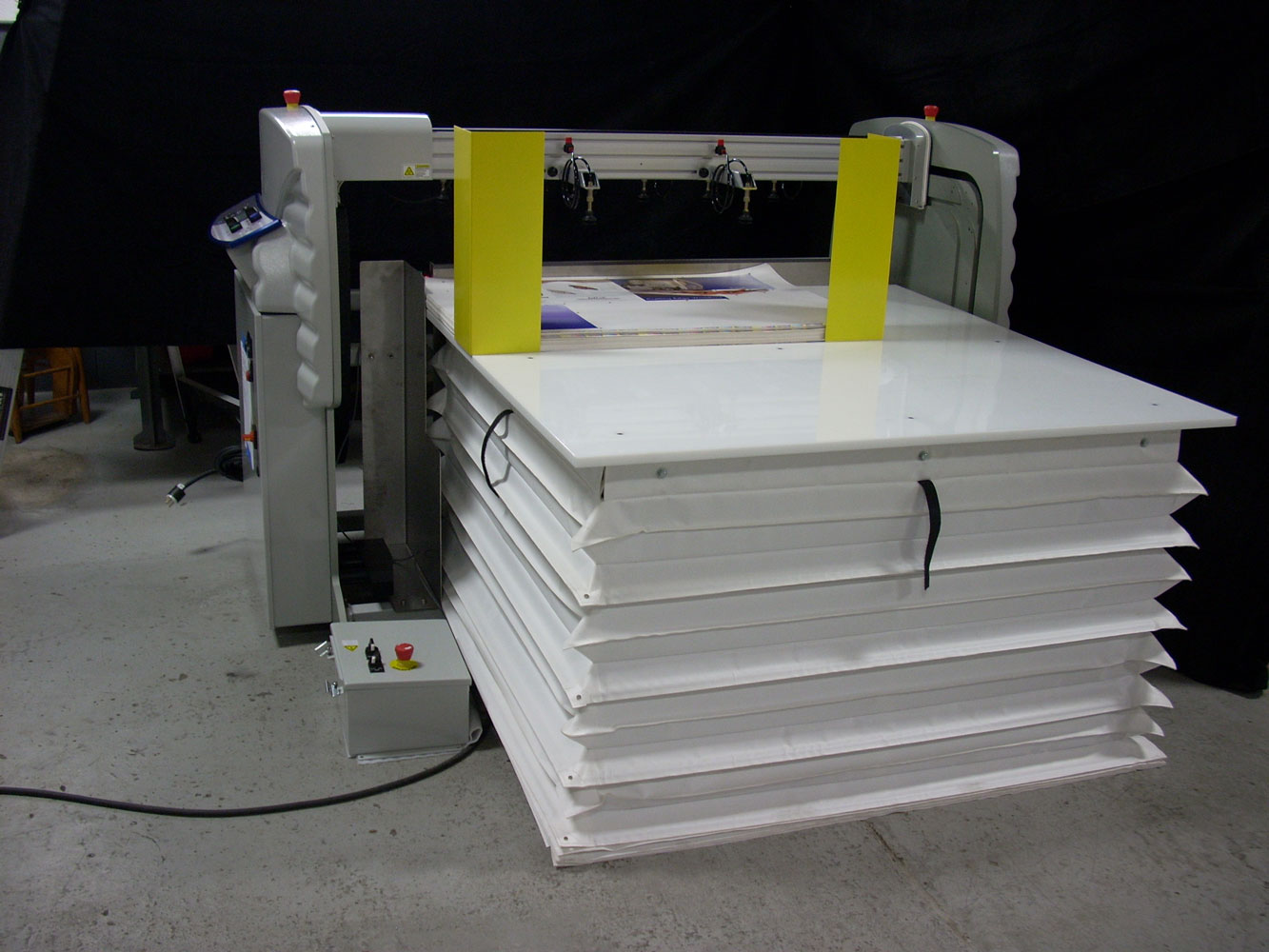

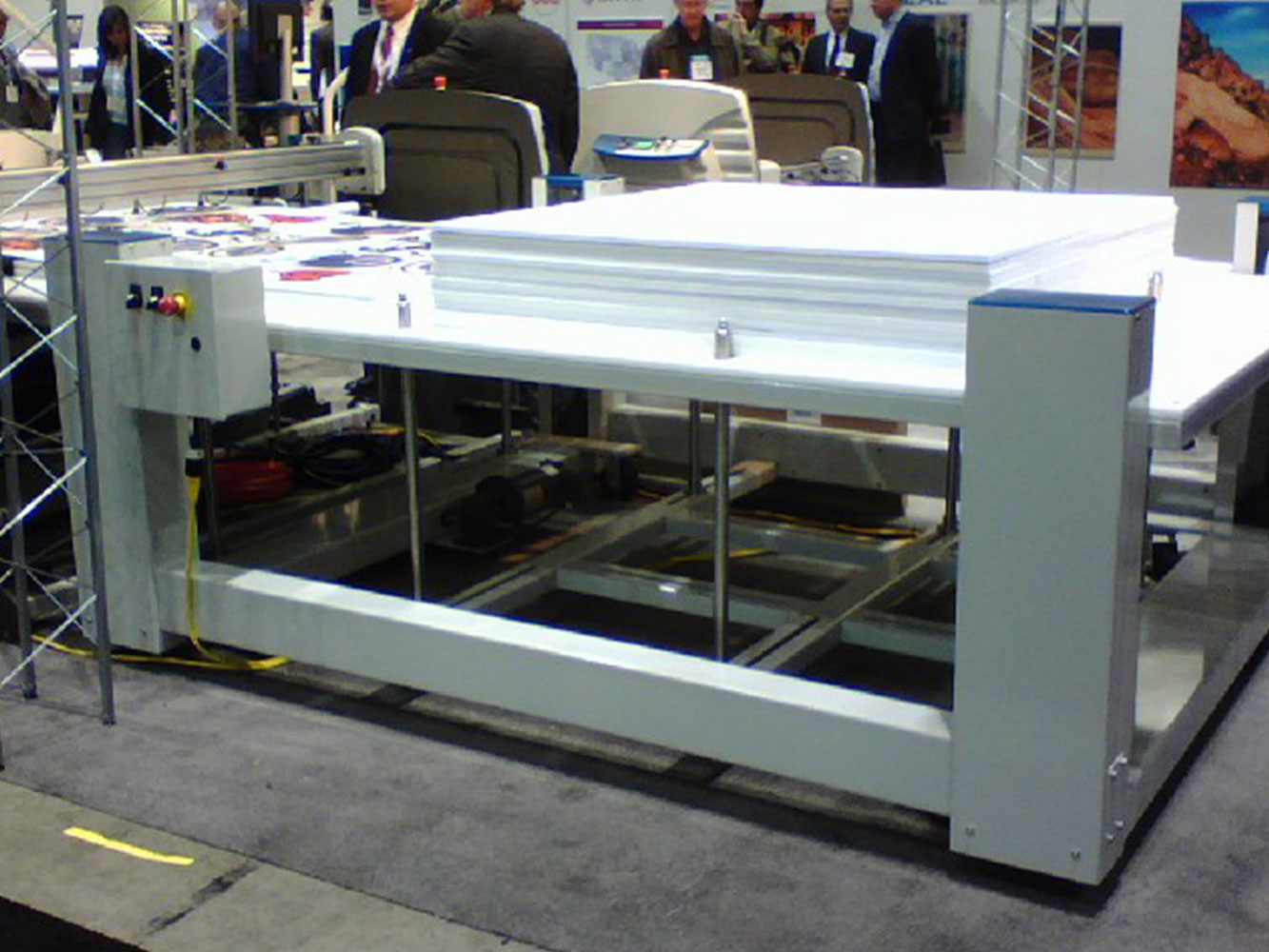

4-Corner Post Feeder/Stacker

A more economical automation alternative incorporating fewer options and choices than our premium machinery but nevertheless containing the essential core elements of pallet load and unload, this simplified feeder/stacker design still gets the job done!

Made to work for virtually any format size, we can customize this basic design to fit your exacting needs!

Key Features

- Pallet Fed Auto Load

- Lower cost solution

- Fully Automated

Options

- Variable width

- Material alignment

Materials

- Up to 3.2 x 2.2M (126″ x 86.6″)

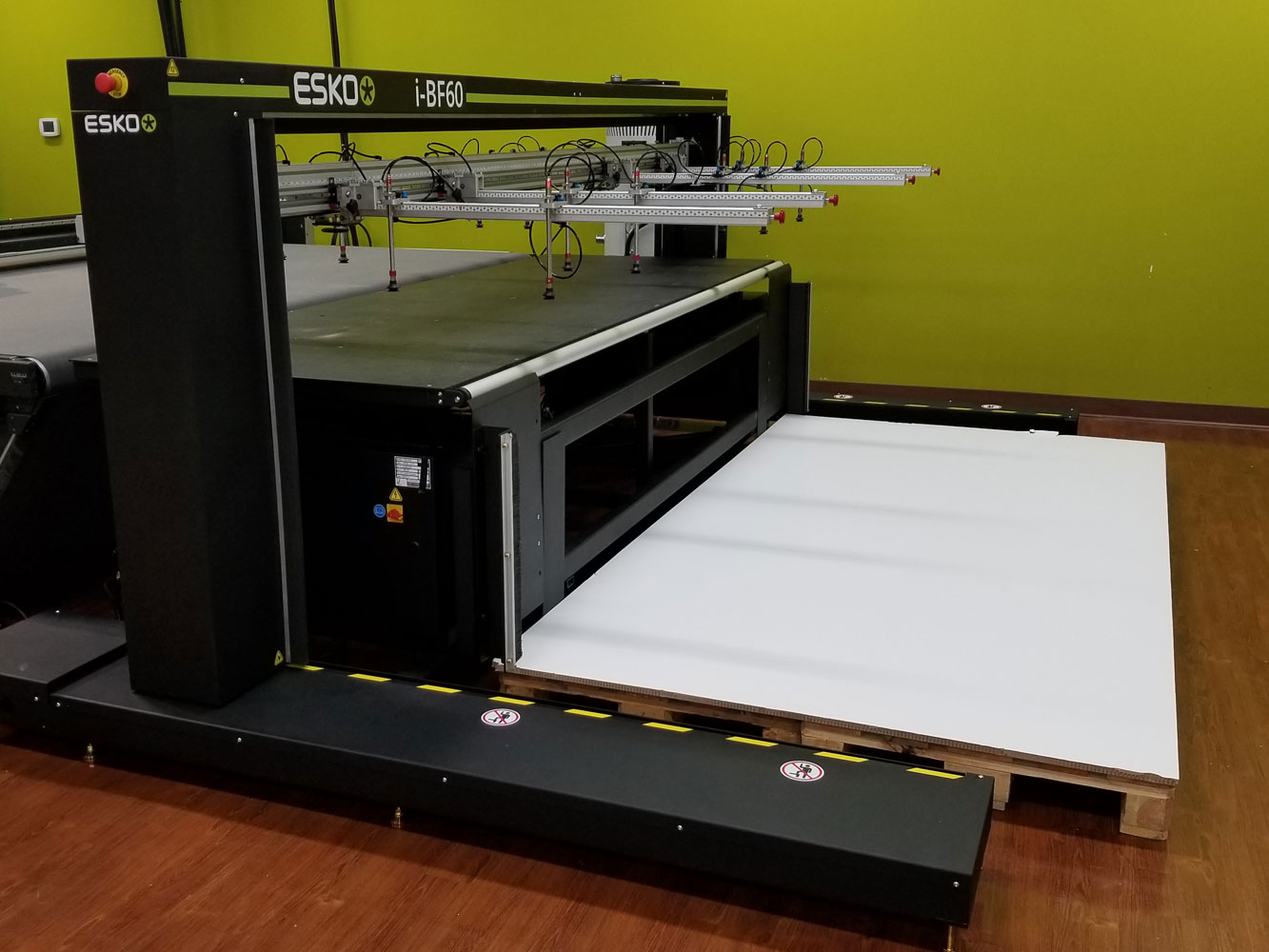

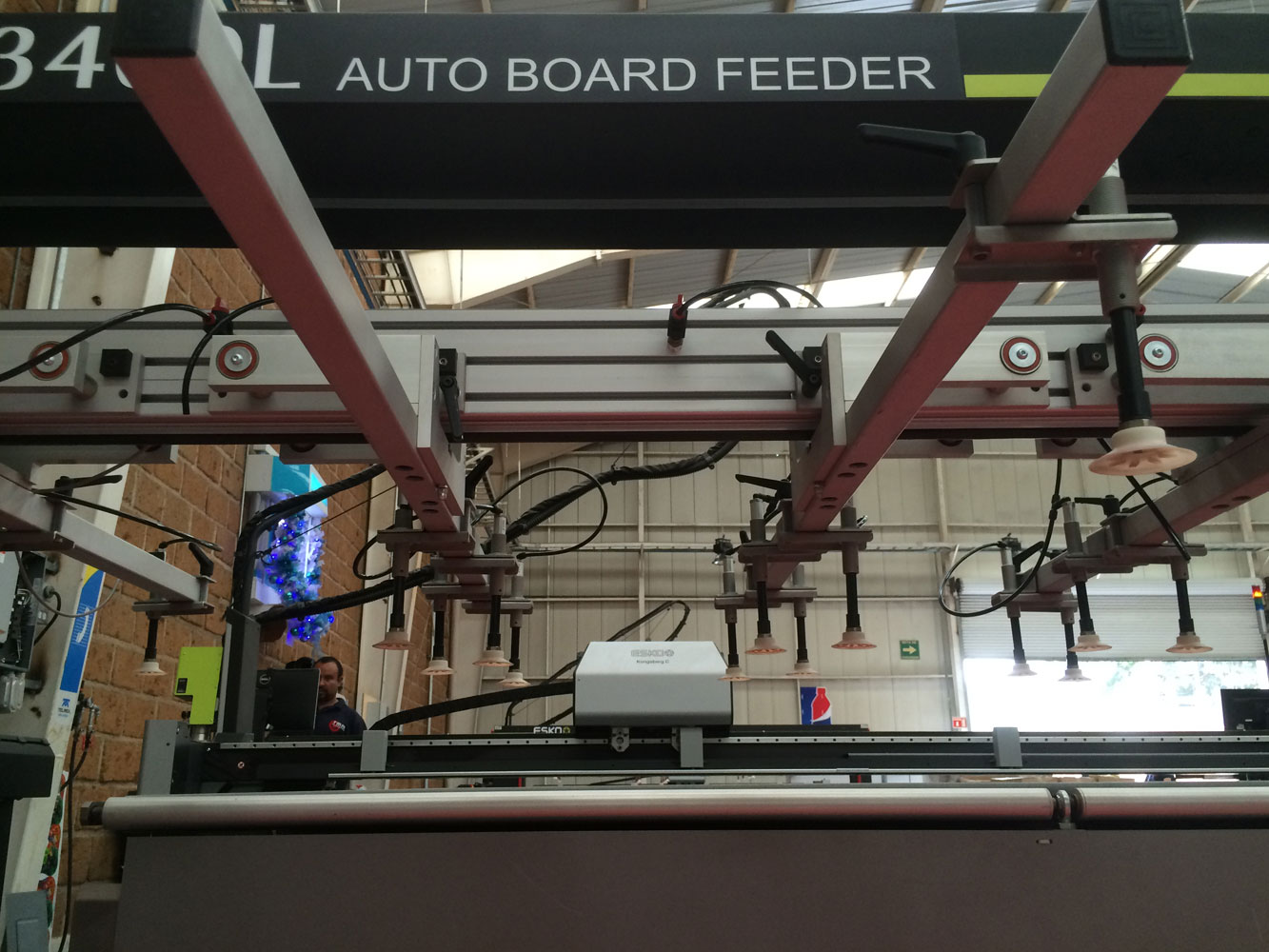

Board Feeder – Semi-Automatic

Key Features

- Manual Load

- Auto-Align

- 1 to 4 Material Lanes

- Left or Right Justified

- CE Certified

Materials

- Up to 3.2 x 2.2M (126″ x 86.6″)

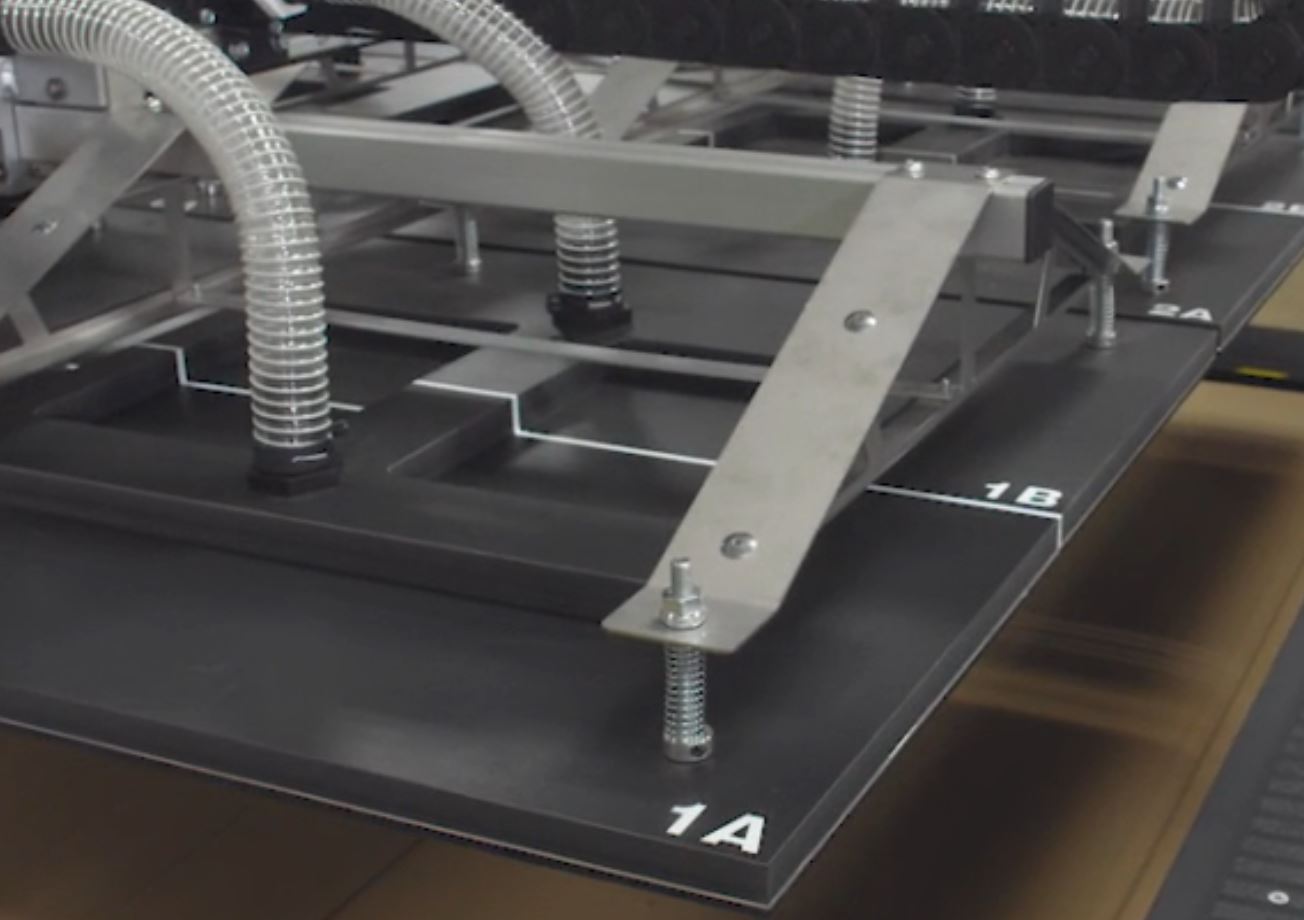

Semi-Auto board feeders are used to stage aligned materials for printing or cutting in a one-at-a-time manner. The operator manually places a board (up to four across) on to the Semi-Auto feeder and presses a “Ready” button. The boards are then mechanically aligned front and side.

When the printer or cutter calls for the aligned board(s), the boards are transferred automatically allowing the operator to “make ready” the next board in succession. The semi-auto feature allows the operator more flexibility to perform other print room or finishing functions because the boards are auto fed when called and does not require 100% monitoring.

Standard Sheet Feeder

The lowest cost automation for the installed base, the standard sheet feeder is designed for short stacks. A motorized single row of vacuum cups is used to transfer material from the stack to the cutter table where the path of conveyance follows a fixed track. Small sheets are carried off the stack whereas larger sheets are dragged off the stack. In both cases, the leading edge of the sheet is handed over to the cutter in coarse alignment.

Key Features

- For installed Kongsberg Base

- Auto Loads

Sheet Feeder Ancillary Equipment

A scissors lift and roller cart system is also provided as optional equipment for the automatic paper sheet feeding system. The roller cart has been specially designed to fit into a flat bed printer for direct stacking of printed materials.

The scissors lift cart is portable and designed to mate up to feed a Kongsberg cutter table.

Ancillary Equipment

- Lift Tables

- Manual Tables

- Roll Off

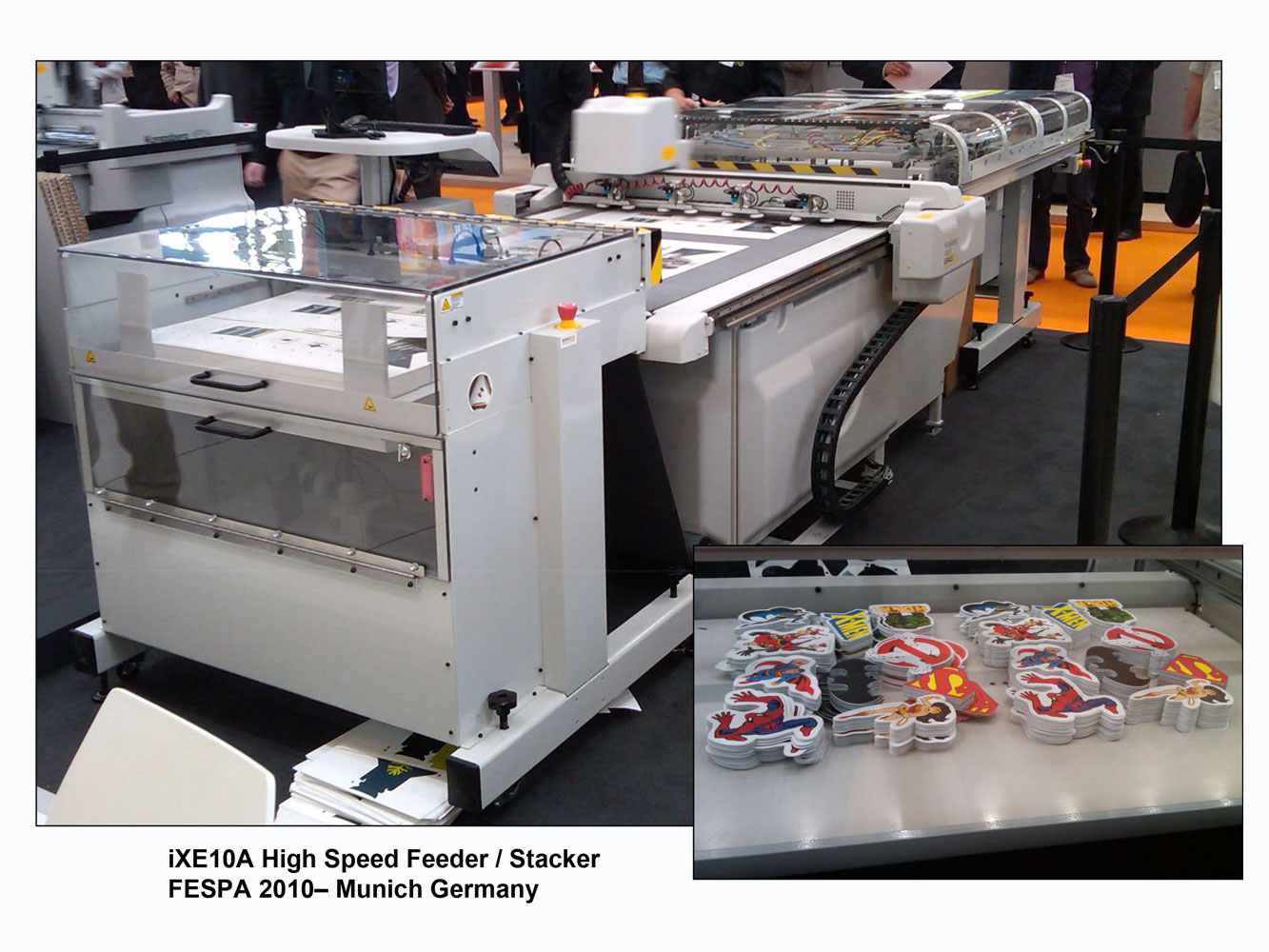

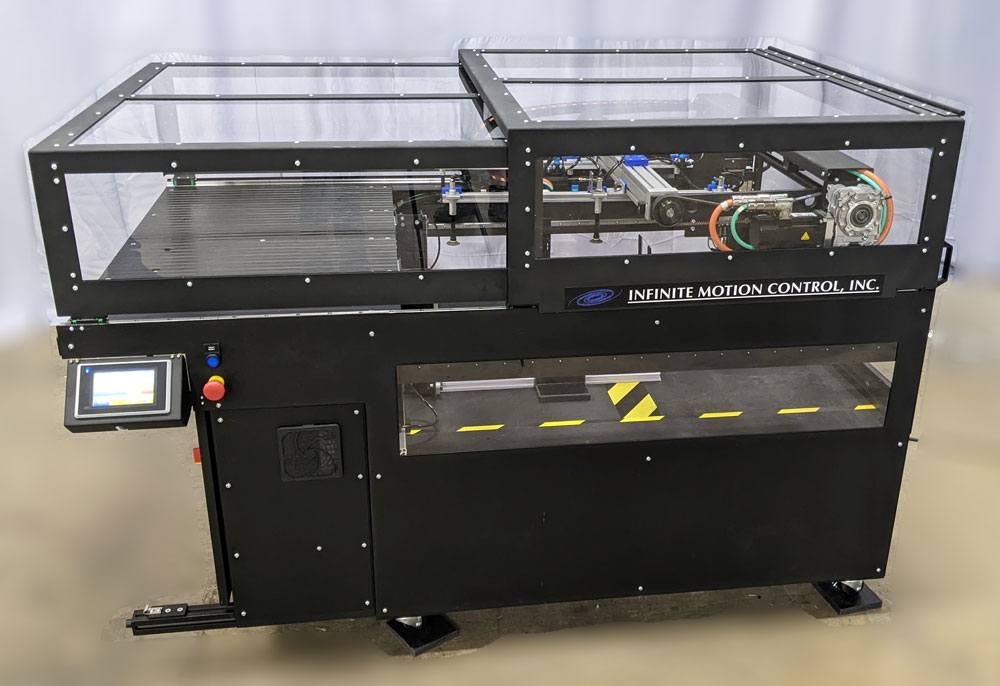

High Speed Feeder (HSSF) and Stacker (HSS)

The High Speed Sheet Feeder (HSSF) is the perfect solution for processing porous and non-porous materials under 32”W x 26” L (810Wx660L mm). This unique design employs suction cup pick devices that are typically used in high speed printing applications.

These suction cup pick devices extend when vacuum is applied to the open cup and quickly retract when the cup seals against the sheet. Double picking of porous materials is reduced significantly by using these devices.

The High Speed Stacker (HSS) is the offloading complement to the HSSF and too processes materials under 32”W x 26”L (810Wx660L mm). Easily configurable for any cut file, 16 independently controlled vacuum pick points extract the cut form from the scrap matrix and place cutouts on to an offload table.

Key Features

- For installed Kongberg Base

- Auto Loads

- Selectable Feeding parameters

Materials

- Up to 810 mm x 660 mm (32” x 26”)

Manual Feed Tables

The Manual Load Table offers an economical method to help reduce delays between indexes by manually loading and registering stage sheets against guide pins. A pattern of grid holes on the top of the table allows for easy change over between varying sheet sizes.

This rugged table design ships flat and is made portable to adapt to changing work flow.