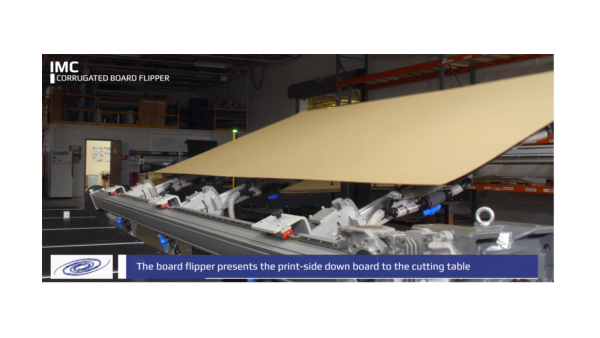

Not all materials ready for printing or finishing are oriented with the correct side up. Infinite Motion Controls in-line board flipper machinery is just the right module to add to your process for reorienting boards with the desired side facing either up or down for downstream processing. This is the right solution to replace manually overturning boards by hand which can be both time-consuming and physically challenging.

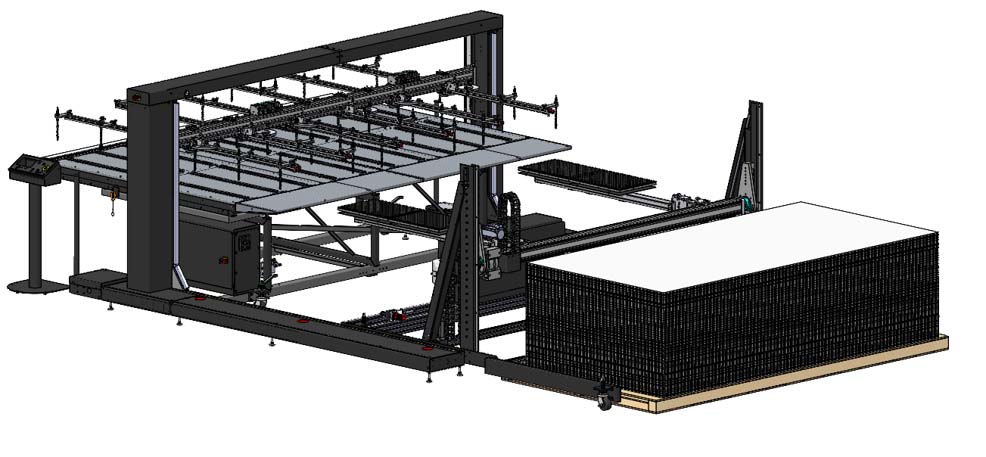

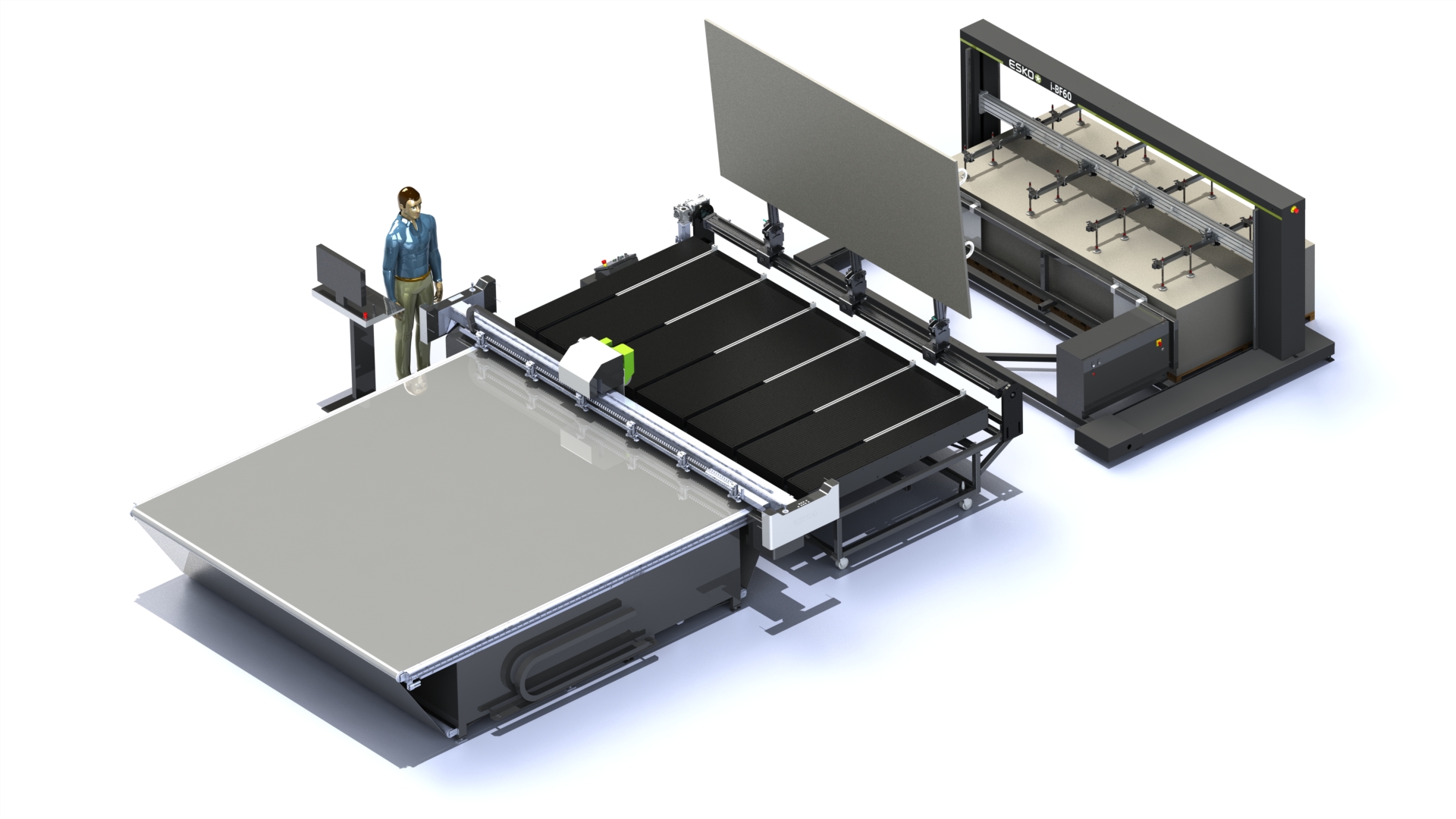

Positioned right after IMC’s infeed ABF, sheets are handed off one at a time to the sheet flipper which over turns the boards (with or without alignment) to the next downstream process. This one-sheet-at-a-time approach flips precisely the number of boards you wish to process and can quickly be changed over to a new board size in minutes. IMC’s board flipper is designed to flip a maximum board size of 5 x 10 ft. in landscape orientation.

Key features

- Inline option with the board feeder

- Pallet to Pallet System component

- Quick changeover of materials

- Rear edge align

- Underside camera ready

Cost reduction benefits

- Reduces employee twisting & bending

- Reduced Board bends / breakage

BOARD FLIPPING

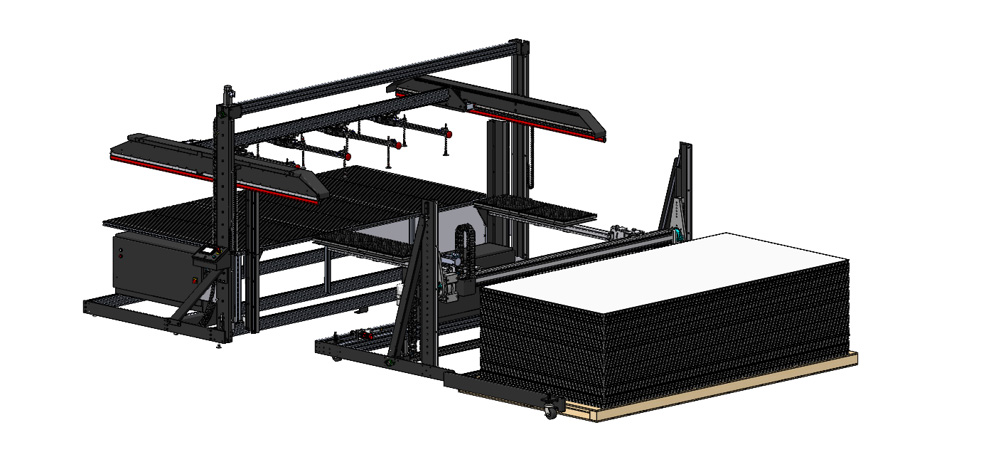

Our adaptable in-line board flipper module has been designed to efficiently flip boards individually before or after digital printing or before digital cutting. The portable nature of the unit allows for easy removal from the production line when flipping is not needed. This system processes boards one at a time, allowing for precise control over the number of boards processed and quickly adjusts for different board sizes with a maximum size of 5 x 10 ft. in landscape orientation.

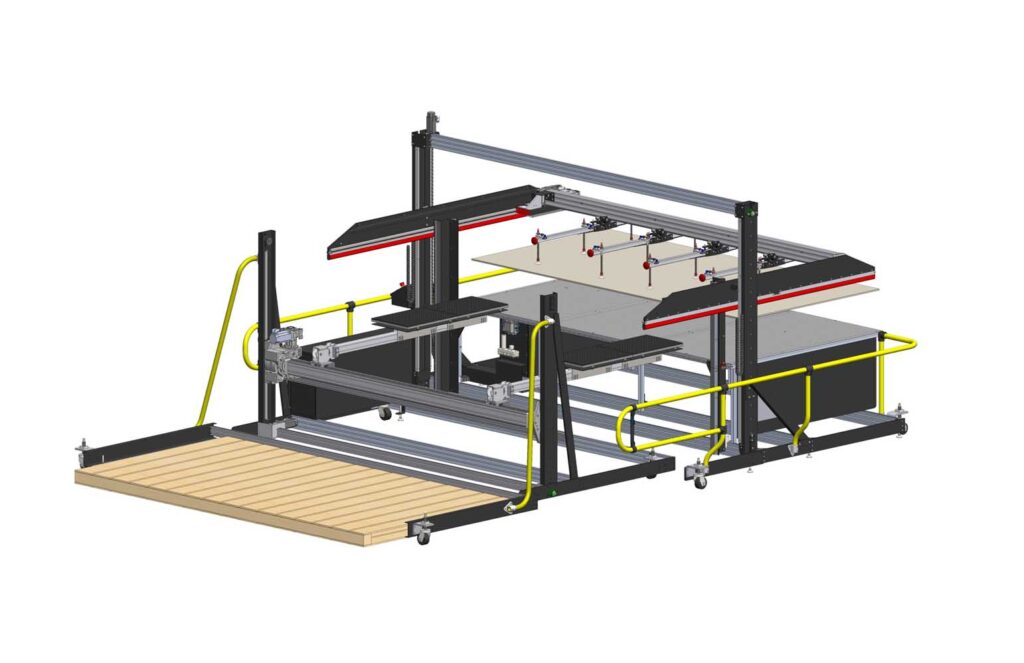

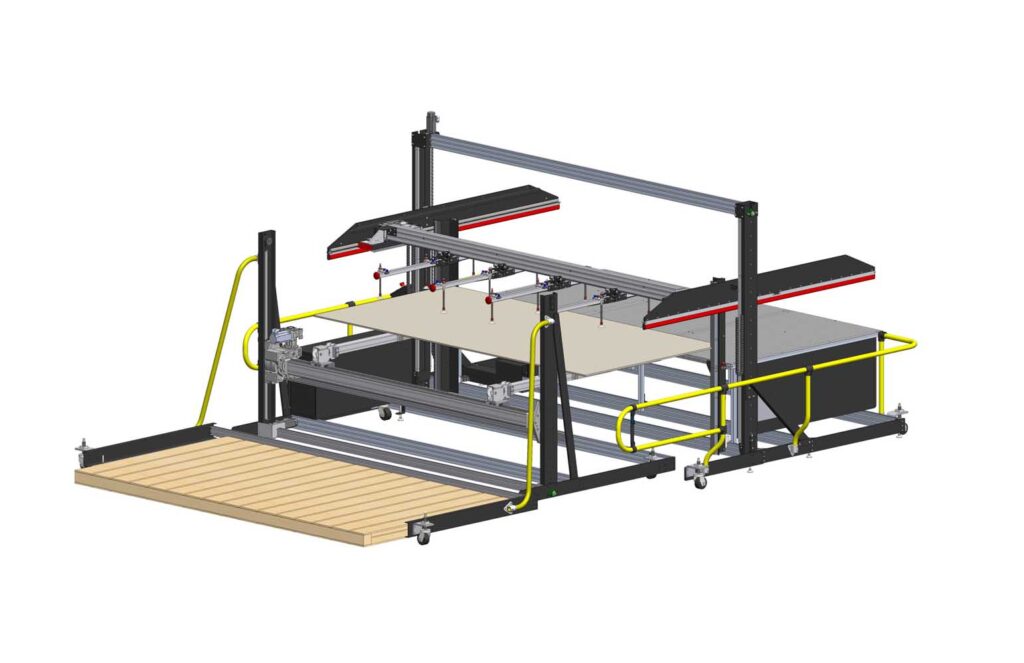

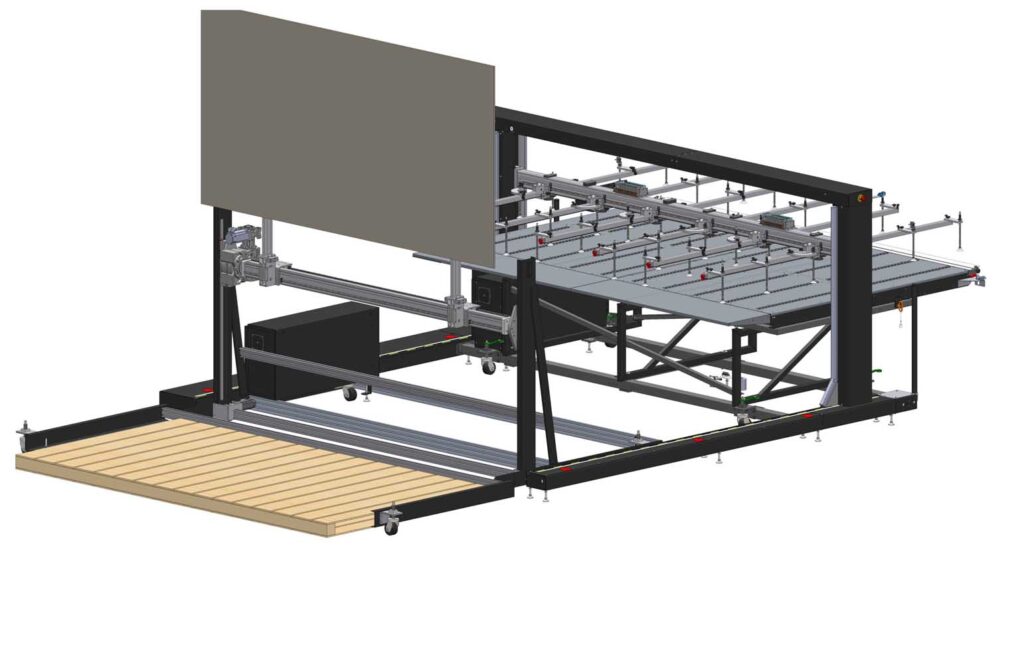

There are two configurations for in-line flipping.

Vector style Feeder or Stacker with Flipper

For Cutting or Printing With or Without Edge Registration

Gantry Style Feeder or Stacker with Flipper

For Printers